Benefits of PCBS Over Other PCB Setting Up Techniques

There's just one service to speak to when you need PCB Assembly services, and that is PCBCart. Take a look at the full listing of these top quality PCB Setting up solutions use:

Full-service PCB Setting Up. This includes everything from PCB Style and also design to full PCB Assembly as well as Examination. You can rely on PCBCart for: Simple parts. Promptly turn your concept right into a reality by using their pre tested, ready to utilize, high quality elements. The best part regarding their "one quit" kit is the convenience of transmitting which permits you to path your board link without fret about soldering parts or soldering.

Full-service electronics and also PCB Assembly. With PCBCart, you get to enjoy the advantages of fast PCB assembly, very easy directing, and one of the most affordable rates in the PCB Setting up industry. You additionally reach delight in prejudiced or two-sided PCB Assembly with their step-up/partial-logic procedure and thermal Mapping tool.

2 sided PCB Assembly. For quickly, inexpensive as well as reliability, choose to use PCBS to make your next PCB. They provide two-way SMT, which means that you can merely position the part into the soldering iron, feed the component's information to the iron, as well as conveniently solder the component. You additionally get to take advantage of their full series of flexible parts as well as standard parts. Integrate this with their reduced rates on SMT elements and also fast SMT transmitting as well as you obtain the ability to create an inexpensive, dependable, as well as reliable PCB Assembly at half the moment.

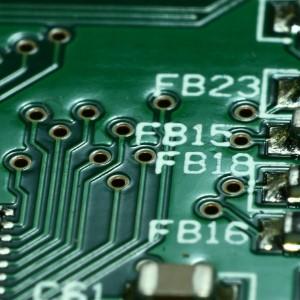

Full-service electronic devices and pcb assembly abilities. Some of the best high quality parts worldwide are put in the PCBS by PCBS Specialized Products. They include a complete range of components and also accessories consisting of: published circuit boards (PCBs), connectors, sensors, pads, wiring, enclosures, headers, resistors as well as more.

Full-service digital and also pcb setting up abilities. The PCBS Specialized Products team supplies you with the capability to select from over 75 different surface mount components and over 80 various positioning options for your board. You have the capability to conveniently purchase your components and also have them fitted according to your demands and also provided to your door. In addition to this, they likewise offer a complete gamut of cord choices to make the assimilation of your digital components as simple as feasible.

One action system. The PCBS team will certainly give you with a complete detailed system that will certainly allow you to swiftly and conveniently construct your pcb setting up without a trouble. Every one of our systems are created effortlessly of usage in mind. This indicates that you will have the ability to put it along with very little time. With our system you will certainly have the capability to change out specific elements or entire PCB packages effortlessly.

Most affordable rate. The PCBS group strives to supply the most affordable prices in the industry. The system allows you to promptly and easily construct a professional looking PCB design with the least amount of time and also cash spent on the entire task. You can make your PCB format with various layers of PCB insulation. You will certainly have the ability to add or remove layers as needed without influencing the end product by any means.

Cheapest labor costs. The PCBS team has actually developed the PCBS (printed circuit card) assembly procedure to need the least amount of exertion for your end result. The web design contains over fifty split PCB layers, so the team has developed devices to allow fast https://kaizentechnology.co.uk/ and also effective production of your project. The pcb manufacturing procedure likewise calls for the least number of workers to complete your task.

Quick inspection turn-around. The PCBS procedure is created with a production line evaluation turnaround time of less than one hr. This is far faster than the common circuit board assembly process and much more economical than different approaches such as hand soldering. This makes the PCBS remedy ideal for business looking to lower the general cost of producing their items.

Complete turn-key pcb setting up services. The PCBS is made with complete turn-key performance to provide you with one https://en.search.wordpress.com/?src=organic&q=PCB Assembly product that can offer the demands of a diverse collection of potential consumers. With an assembly-line assessment procedure that takes simply thirty minutes, your group can quickly create several PCBs from start to finish. This flexibility makes the PCBS option a one-stop service for your manufacturing requirements. Even more, the complete turn-key pcb assembly solution includes product screening and also prototyping at any of our fabless manufacturing facilities situated across the globe.

Streamlined PCB order gratification. Due to the fact that the elements are patted through-hole, they can be packaged and delivered with minimum added charges to your consumers. By paying much less than the typical method of creating PCBs, the pbst's simplified packaging and shipping procedure deal phenomenal value to your advertising and marketing spending plan. The combination of low-cost, high-volume as well as no issues production suggests that your consumers are not paying full-price for your parts' any kind of longer.

PCB Setting Up Processes and the Final Evaluation Techniques

Among the crucial consider each PCB setting up task's general efficiency is that of the client s expertise of Bittele's procedure. The number of actions entailed varies according to the type of job concerned, as detailed in the flow chart below, and also all of these actions are defined in detail in the below mentioned article. This write-up has actually been prepared in order to aid you in a very simplified manner in relation to your PCB Setting up service. You will certainly see that each step is explained with an illustration. You will additionally see that a few of these pictures can be discovered in several various other PCB Setting up tutorials on the web. So if you are unclear of any type of step, you must absolutely describe these resources.

Among the initial points you will certainly observe, when you see the flowchart, is that it has a "blue" colored circle that represents the beginning of the process, which is called "PCB Setting up Ability Screening". This will certainly be followed by "PCB Inspection", which is a PCB test http://www.bbc.co.uk/search?q=PCB Assembly that checks the alignment of all elements. Next off, there is a "PCBS Completion Process", which is consisted of "PCBS Manufacture As Well As Assembly", which entail "PCBS Components Setup", which permits you to develop the PCBs on the computer system, after which "PCBS Assembly Service" will certainly complete the work. At this point, the process has come to an end as well as is stood for by a strong black line. By comparing this to the image at the start of this short article, you will certainly see that the complexity of this particular job has actually already been reduced, which indicates that the time required to complete the entire procedure has additionally been reduced.

Currently allow us take a look at the following part of the setting up procedure - PCB Assembly solution. In this phase, your task is to give services to the PCB suppliers. Depending upon the intricacy of your tasks, you will either need to install as well as put together just surface mount parts, or both surface area place components and also put together parts. You can make use of either ribbon wire or hook cables in order to feed elements into the PCBs.

The following step consists in using "PCBS soldering weapon" or "PCBS stipple" equipment to feed elements into the PCBs. Components can be fed utilizing "PCBS tabs" or "PCBS openings". Then, the last part that will be added to the PCB is "PCBS header". The mix of parts will allow your custom electronic item to operate. The setting up of these parts will be achieved with "PCBS lamination", "PCBS heat-rolling" and "PCBS pressing".

You might ask yourself why I mentioned "through-hole technology" right here. It is due to the fact that through-hole innovation reduces the variety of openings that require to be drilled right into your elements in order to feed them through the PCBs. The variety of holes that are required to feed parts through the PCBs depends upon the density of your PCB as well as the weight of your electronic item. You will discover that the quantity of PCBs is not a limiting variable. This approach enables manufacturers to create huge amounts of PCBs in a short quantity of time, which can enhance production time, decrease material expenses and also enhance success.

PCB Setting up can likewise be boosted with the addition of a conformal coating. A conformal layer assists to secure your PCB from wetness absorption and also corrosion. Along with this, it also assists to add strength to your PCBs, boost their electric and physical homes and also to enhance their sturdiness.

You will discover that the majority of PCB Setting up makers provide PCB Assembly services to consumers worldwide. Most of them provide PCB Assembly to customers in Canada, UK, Australia, Japan, China, Korea, Taiwan and also numerous various other countries around the globe. You ought to keep in mind that the PCB suppliers in these countries need to abide by PCB Setting up needs, which are various from typical production criteria. These companies likewise utilize last evaluation techniques that entail various examinations as well as evaluations prior to the setting up of last motherboard.

PCB Assembly business typically use a final inspection approach referred to as place screening, which helps to validate the feature of the last PCB Setting up. You will require to make certain that the parts you pick for PCB Setting up remain in good condition, without issues or missing parts. PCB Setting up companies use numerous various approaches to identify test their PCBs as well as last assessment approaches may vary, depending upon the requirements of your project.

Everything About Plasma Cutters, PCB Assembly and More

A turnkey PCB Setting up is an organization situation that defines the manufacturing of top notch, personalized published motherboard (PCBs) with one supplier. The term "turnkey" typically refers to a product that is provided to the customer as a full, ended up product. Simply put, business would develop the products along with the PCBs internal, while retaining an agreement with a supplier for the manufacturing solutions. In many cases, a firm could make a decision to work with only a PCB manufacturer, retaining the solutions of just the vendor that develops the PCBs. The majority of complete cases include a mix of solutions, where a company would certainly create the PCBs and afterwards agreement with a PCB producer to offer assistance and warranty.

The PCB Setting up solution is typically supplied by firms that focus on the design, advancement as well as manufacture of printed circuit card(s). These firms have comprehensive understanding as well as experience in creating and fabricating excellent quality PCBs. Commonly they will certainly likewise have the additional skills and resources to enable the PCB Setting up to be completed within the quickest period of time possible. The majority of these firms provide a complete variety of PCB services, that includes excellent quality style, screening, product sourcing and also assembly. A few of these solutions consist of:

- PCB Assembly solution offering companies will certainly additionally do a total assessment of the end item, including material sourcing, design, testing and manufacturing. During this assessment the company will check all components to guarantee they are of the finest. - Several PCB Assembly solutions provide pre-manufacture testing and also assessment, which can verify that all components fulfilling stated specifications, have actually been correctly wired as well as produced to OEM criteria.

- PCB Assembly service providers can likewise use an electronic proof of purchase. The receipt is made to prevent warranty fraudulence. It supplies proof of the beginning of the item, which allows the customer to confirm that the origin of the thing can be mapped back to the PCB Setting up producing procedure, or that a non-authorized representative supplied items. - A thorough and also comprehensive assessment of the final product, carried out by the client, will give conclusive proof of the nature as well as source of the defective product.

-PCB Assembly solution supplying firms can provide a totally documented approach of tracking the production process and also quality assurance. The majority of PCB Setting up solution supplying firms will have an on the internet radar, through which clients can check out and also monitor the assembly development of their products. - The majority of PCB Assembly service offering business provide a complete selection of high quality internet parts. They typically have a huge, totally automated tooling facility, where they can rapidly produce hundreds of PCB's. - comprehensive understanding of standardized elements and their variations makes it simple for customers to incorporate them right into their very own unique item layouts.

- Extremely experienced PCB Setting up company can additionally supply pcb surface install components, and also solder paste ranges. Their solder paste items are extremely functional and also economical and can quickly integrate into a wide range of layout suggestions. - Another option offered by several suppliers is the capacity to integrate different product components right into one product. In this situation, the customer simply purchases the pcb itself and afterwards has the alternatives of including solder paste elements, or custom-made components. - Lastly, it is feasible to use a mix of solder and surface area install elements, in order to save cash.

- If you would love to create a PCB from the ground up, without needing to count on a prefabricated product, there are 2 choices available to you. One option is to buy a readily readily available PCB Design and Format software program. This sort of program will certainly enable you to easily create your own pcb setting up. The other choice is to get PCB Style and also Format solutions from a specialist provider of such services. Although the price of such a service might be somewhat higher than the price of acquiring a commercially readily available PCB, it will certainly make certain that you receive high quality items, with top-notch layout as well as format outcomes.

Regardless of the technique you choose to create your brand-new PCB, it is essential that you extensively comprehend how each technique functions, prior to you start. PCB Assembly is a procedure that requires accuracy equipment, expert style and first-class results. If you have any questions concerning the process or would like to learn more regarding the most effective types of PCB Setting up, please do not hesitate to call us. Do not hesitate to discuss your individual tasks, or publish any concerns that you might have right here.